Thread whirling unit

Item Number : CTLA545201

Feature : Thread whirling - the innovative tool for thread machining

Machine : Citizen

- L20VIII/IX/X/XII (2M8/2M9/2M10/2M12)

- L32VIII/IV/X/XII (1M8/1M9/1M10/1M12)

The thread whirling unit is a novel thread machining process that utilizes hard alloy forming cutters mounted on high-speed rotating cutter discs to form threads through high-speed milling of the workpiece. Named "thread whirling" due to the swirling cutting splashes during the machining process.

The thread whirling unit from SONG GIA enables highly efficient production of medical threads such as implant screws and bone screws. We focus on enhancing the processing of medical threads transitioning into double threads, ensuring efficiency and quality throughout the machining process. Achieving high-efficiency thread machining with just one feed-in.

●Applications:

Suitable for Swiss-type lathe machines, efficient machining of bone screws, miniature threaded rods, small lead screws, and similar thread machining in the automotive industry.

●Product Features:

|

No need to disassemble from the machine, simply loosen the screws, and the cutter disc can be quickly replaced behind the tool holder, reducing replacement time and increasing efficiency.

●Advantages:

Compared to traditional thread machining methods, thread whirling has the following advantages:

1.Forming machining, one-cut shaping, no need to retract the cutter, high precision.

2.Efficient machining can increase processing efficiency several times or even dozens of times.

3.Easy installation. No need to modify the machine tool structure. Spiral lead angle adjustable.

4.The tool holder serves as a special tool and achieves fully automatic machining under CNC system control.

We now have thread whirling unit for STAR, Tsugami, Citizen, HANWHA, JINNFA.

Other brands can be customized upon request.

Detailed specifications

| Speed ratio : | 1:1 |

| Maximum speed : | 6000RPM |

| Tool clamping : | Utilis no.119287 |

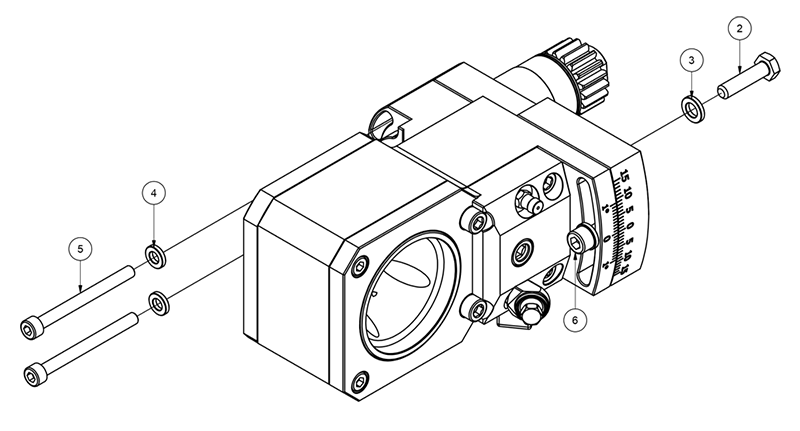

Instructions(一)

Installation on T09

Installation steps:

一、 Put thread whirling unit on T09.

二、Secure thread whirling unit with washer③ and screw②.

三、Secure thread whirling unit to the machine using washers④ and screws⑤.

四、When adjusting angle:

Loosen screws⑤ and screw⑥ to adjust angle.

Secure screws⑤ and screw⑥ to fix angle.

Note: When installing on T09, T08 and T10 can't mount the tool holders.

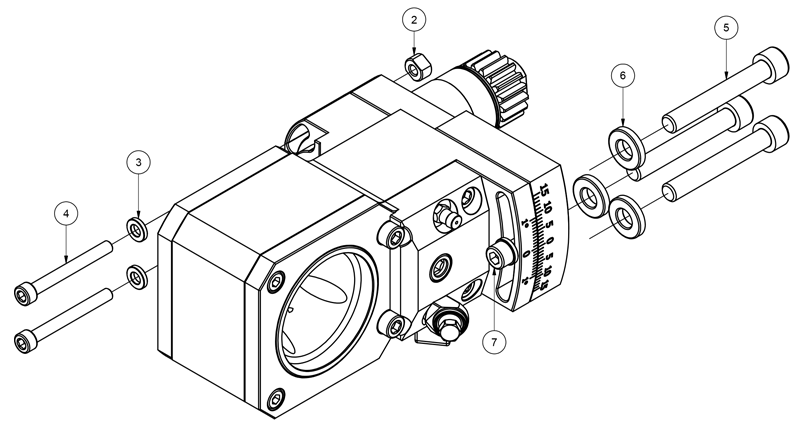

Instructions(二)

Installation on B-axis

Installation steps:一、 Put nuts② in the hole.

二、Secure nuts② with washers③ and screws④.

三、Secure thread whirling unit to the machine using washers⑥ and screws⑤.

四、When adjusting angle:

Loosen screws④ and screw⑦ to adjust angle.

Secure screws④ and screw⑦ to fix angle.